Juggling Jerry Jugs

Foundation Findings #43 - September 2007

For this Foundation Findings, we took a closer look at portable fueling containers, also known as jerry jugs.

Why Jerry Jugs

We often hear that unintentional drips from jerry jugs are a common source of annoying, accidental fuel spills and that tell-tale rainbow sheen on the water.

Whether filling up a small outboard engine, a personal watercraft or transferring fuel from a container to a larger boat, jugs are often hard to manage. Not only are they heavy and tricky to balance, but gaskets, nozzles and air vents leak with near-certain predictability.

In boating, jerry jugs are nearly as common as fuel. In recent years, the design of the common jerry jug has changed to meet new laws restricting distribution to jugs that have features to prevent pollution and increase safety. So when boaters go shopping for a new jerry jug, they might not be able to find the familiar models of yesterday. In fact, the standard, free-flowing jerry jug with separate vent hole is currently banned from sale in 13 states and that number is rising. The EPA expects all 50 states to be affected by the end of 2009.

What's Changed? CARB vs. Non-CARB

Foundation staff performed tests evaluating self-venting and auto-stop features, flow rate, and leak prevention. But first, we compared how well the new designs prevent emissions from evaporation of fuel through the sidewalls and nozzle of the tank.

The evolution from the fast-flowing, messy jugs of the past to a more controlled, slower-flowing product is largely in response to the California Air Resources Board (CARB). Their 1999 adoption of regulations to control the amount of smog-forming gases that escape from ordinary fuel containers set the standard for jerry jug design in California.

CARB established requirements for five-gallon and smaller portable fueling devices (containers larger than 5-gallons are exempt) to curb vaporous emissions. In the process of addressing the release of fumes through the nozzles, vents and even the plastic sidewalls of the jugs, new features also targeted the leaks of fluid contents through better nozzle design. Features of new CARB-compliant jerry jugs include a single opening for pouring and venting, treated polyethylene plastic for low permeation, and an auto shut-off, self venting nozzle which springs closed when not pouring.

Currently, the following states have adopted CARB requirements and retailers may only sell CARB-compliant jerry jugs: CA, CT, DC, DE, ME, MD, NH, NJ, NY, OH, PA, TX, and VA. Eventually, you may not be able to purchase anything but CARB-compliant jugs, as the EPA estimates nationwide compliance by 2009.

Fill 'er Up! - Testing Protocol

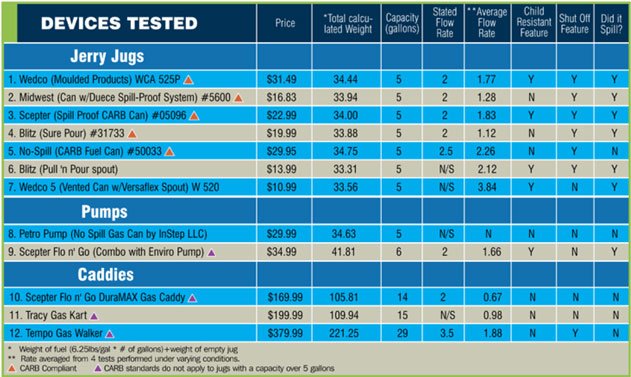

With three categories of products to evaluate, we had a lot of work to do. We first compared the traditional jerry jug to newer jugs with additional spill and pollution prevention features. In a separate category we called “Pumps”, we assessed portable fueling containers that included integrated siphons or gravity pumps designed to help ease the transfer of fuel and relieve the stress on your back. Finally, we evaluated a few larger, wheeled devices called gas caddies that can make the transport of larger quantities (14 - 29 gallons) easier.

We searched boating stores, auto parts vendors, specialty shops and the Internet to gather our test products and ended up with seven jerry jugs, two pumps, and three gas caddies. Five of the jerry jugs were CARB compliant and two were the traditional non-CARB design. One of these non-CARB jugs served as our control in flow rate tests - it had a separate vent and had no cut-off devices to restrict or regulate flow.

We anticipated spills so we used only water, not fuel, for all of our flow-rate testing. For our first round of testing, we constructed a mock-up of a boat's fuel fill and recorded the length of time it took to empty the entire contents of each jug, and then measured the flow for one minute of pouring For the next round of tests we used our 22' center console power boat with horizontally mounted deck fill on the gunwale. After disconnecting the fuel line and capping it off to avoid getting water in our fuel tank, we again measured the total fill time and one-minute flow rates. This first round of testing on the boat took place on dry land with the boat on a trailer.

Though the spring-loaded tabs were designed to prevent leaks, they didn'’'t always work well, splattering fluid when the tab slipped off the side of the deck fill. These tabs weren't very sturdy either, showing significant wear after only two or three fills. After a dozen uses, it may break altogether. One tester commented that we'd probably have to jury-rig the jerry jug, circumventing the safety feature, to make it pour at all.

To add another realistic variable to our testing, we conducted our second round of testing at a marina, filling both from the fixed dock and from inside the boat as it rocked with the passing waves. This also provided us with a realistic scenario for lifting a full jerry jug from the dock and over the gunwale to a passenger in the boat. By the end of the day, we were all sore from repeatedly hoisting jugs that weighed over 30 pounds. But we learned a great deal about the pouring characteristics of each product and how the design affects the likelihood of spills.

Results: The Jerry Jugs

In our tests we compared flow rates of each of the CARB-compliant jugs with the non-CARB control paying close attention to the ease of use and spill potential of each product. The five different brands of jerry jugs we tested included Wedco, Midwest, Scepter, Blitz and No Spill, all of which were CARB compliant. The two non-CARB jerry jugs were both made by Wedco.

It was no surprise that the control jug, the non-CARB Wedco with the Versaflex spout, flowed the fastest. It was also the messiest, gushing over the side of the gunwale on every pour. The other jugs certainly flowed more slowly, but many spilled significantly less.

All of the CARB jugs claimed a flow rate of 2 gallons per minute (gpm) with the exception of the No Spill which claimed 2.5 gpm. In our timed tests, we noted that none of the jugs met its flow-rate claim. The non-CARB jugs did not specify a flow rate but easily beat the claims of the CARB jugs. Although speed was not the point of our testing, we did find it terribly tiresome to balance a fuel can for several minutes while the slow CARB jugs trickled fluid through self-venting nozzles. In comparison, our super-speedy non-CARB control jug emptied in about one minute.

Since these jugs weigh over 30 pounds when full, we found the jugs with more handhold options were easier to handle. The Blitz and Wedco each featured two handholds to help with balance.The No Spill, with its L-shaped nozzle, worked best for our boat and was unanimously voted the staff favorite. It rested comfortably on the gunwale of our boat and with the same push-button valve as a 2.5 gallon jug of water it spilled the least of all the jugs. Flexible spouts are not feasible on CARB jugs because of the shut-off feature requirements. So directing fuel into the deck-fill was a challenge when things like railings and cleats got in the way of angles nozzles.

Some cut-off mechanisms were also difficult to maneuver around obstacles. Each CARB jug features either a tab or collar on the nozzle that must be depressed before the flow begins to prevent any premature spilling. However, you must use a constant downward force to maintain the flow, which would preclude any use of a funnel. If you let up on the pressure, the flow will slow and even stop so that when the jug is removed from the fill hole, the flow of fuel will cease. The CARB jugs also have an auto stop feature that shuts off the flow when the fuel in the target tank reaches the nozzle tip. Since the CARB nozzles are self-venting (meaning that through the nozzle fuel flows out and air comes back into the jug at the same time), simple physics stops the flow when air can no longer reach the nozzle.

In general, the auto-shut off features and the spring closures did a good job preventing leaks of fuel and fumes, especially when the jugs were new. However, the plastic nozzle hardware began to show signs of wear after just a few uses, resulting in more drips. The only exception, was the No Spill. Its nozzle required the tester to press a release button with springs that were exceptionally stiff.

Although the CARB jerry jugs flowed slower than the control, we still encountered our share of leaks. Some of the jugs required that gaskets be properly installed in the nozzle, others were prone to cross threading, and some just didn't stop the flow quickly after release. Since the jugs can't be used with a funnel there was nothing to catch a few drips. Couple this with the dramatic damage sustained by some nozzles after a half-dozen uses and we felt that many of the jugs actually failed to prevent leaks.

The Pumps - Enough of the Lifting

The next product category aims to ease back strain by including an integrated hand pump. Neither of the two pumps tested were CARB-compliant. The Petro Pump has a 5-gallon capacity and features a small plastic pump handle. The Scepter Flo n' Go has a capacity of 6 gallons with a long hose and trigger-style handle that must be primed by squeezing several times to begin the flow. The Petro Pump requires continual pumping of the handle to maintain flow. To prevent dripping, we had to let the excess fuel in the four-foot hose drain out before removing the nozzle from the deck-fill. With a nozzle that fit easily into the fill hole, this pump delivered a directed flow and was easy to control, since there is no need to lift the jug. However, the delivery speed was painfully slow. We calculated a flow rate of just over 1 gallon per minute and a total of over 200 strokes to empty the jug in five minutes. The advantage of this device is that it can pump uphill, but all that pumping quickly fatigued our testers who had to change hands frequently because of the strain.

The Scepter Flo n' Go did not require such repetitive motions when pumping on a level surface or downhill, and once started it would continue smoothly. However, this was only true if the target tank was lower than the jug itself. As a gravity fed device, it was painfully slow and nearly impossible to empty completely. Trying to pump into our test boat from the dock was very difficult when the deck fill was more than 2 feet from the dock surface. According to the pictures on the packaging, you can pump up hill, and we certainly tried, but we gave up after having to squeeze the handle again and again to continue the flow. This device is definitely best suited as a downhill gravity fed pump.

Both of these devices have long hoses that are prone to dripping residual contents, they are slow and fatiguing to use, and neither one is CARB-compliant so the staff could not recommend them.

And Away We Go - Gas Caddies

The obvious advantages of gas caddies are portability and a larger carrying capacity. One major disadvantage however, is weight. The strong reinforced plastic, beefier handles and wheels to ease transportation are all welcome, if not necessary features for a device that weighs about 100 pounds, or more. Besides the larger capacity, the caddies sported 6" solid wheels (the Tempo has 10 inch wheels) which made pulling them down the dock a breeze. After the chore of crossing the gravel parking lot the dock was a treat. The gas caddies can save you the trouble of having to carry multiple jugs but they are very heavy when full.

First we evaluated the 14 gallon Scepter Flo n' Go Duramax Caddy, the larger cousin of the 6 gallon Flo n' Go Combo Pump we also tested. Its pump system is identical to the smaller device, and we encountered the same frustration - it wouldn't pump up hill effectively. We followed the instructions to the letter and even elevated the caddy, but we still could not empty it. The stated flow rate is 2 gpm, but we observed a mere 0.67 gpm. On a positive note, this caddy did not leak. When your target tank is full, simply release the pump handle, and tap the nozzle lightly to release the last drop before removing from the tank.

The Tracy Gas Kart had a 6' rubber hose with a brass shut-off valve. We also ordered for the Gas Pal pump kit, a $54.99 option, so we could test its ability to pump uphill. This optional pump mechanism appeared to be the identical the Petro Pump that we tested earlier. It was similarly slow and required hundreds of strokes to empty the caddy's entire contents. To make matters worse, the pump broke midway through our initial tests. We removed it and installed the spare pump - it too broke, this time leaving us fishing for pieces that fell inside the tank. With no other options, we decided to continue the unit's evaluation as a gravity-fed pump. The brass shut-off valve was a very effective cut-off device. Although it lacked the style and comfort of a nozzle handle, it was easy to direct and didn't drip once the valve was closed.

The third gas caddy in our line up was the Tempo Gas Walker. It was the largest of the caddies, weighing 221 pounds, and required two people to lift into the back of a vehicle. We were thankful that it had large pneumatic tires. It rolled over the gravel parking lot easily. However, when rolling the full tank over uneven ground the whole unit it became slightly unstable. It included a 3/4" Goodyear fuel-rated hose and a sturdy metal pump handle, similar to the style you'd encounter at a service station. It also came with a grounding wire to prevent static charge build up. The biggest draw back is perhaps its price - $379.99. We decided not to order for the rotary pump, which was another $147.25 and instead tested the Gas Walker as a gravity-fed pump.

Very specific transportation instructions included with the unit say that when transporting this caddy from the service station, you’ll need to affix a red diamond-shaped Flammable Liquid placard in clear view on the rear of the vehicle. Because its capacity is greater than 20 gallons, national DOT regulations would classify a vehicle carrying this caddy as HAZMAT. In some states though, a vehicle carrying as few as 9 gallons can be considered HAZMAT.

The Gas Walker's stated gravity flow rate is 3.5 gpm, however, the best we could get was just under 2 gpm. The pump handle and the brass shut-off valve allowed testers to precisely control the flow of fuel with no drips. This was a solid unit and solid performer although not as fast as we would have liked.

If one of these larger caddies is right for you, remember, always use two people to move heavy gas caddies into and out of your vehicle when full. These units are heavy!

Where Did the Fuel Go?

CARB estimates that each year, literally tons of vaporous emissions escape from small portable fuel tanks and therefore requires thicker plastic in the side-walls of jugs as additional prevention. So, we decided to set up a back-yard experiment and see for ourselves.

We took two jerry jugs from the same manufacturer and put them to the test. One jug was CARB-compliant and the other was non-CARB. The only difference between the two was specially treated polyethylene plastic in the CARB jug that is intended to reduce fuel evaporation through the tank walls. Other than the treatment, both cans were identical. We filled both cans with an equal amount of 87% octane fuel, weighed them and put them in the sun for a few months. The results surprised us.

After four months of exposure to direct sunlight in the day and cool temperatures at night the CARB jug had no change in weight. The untreated non-CARB jug lost nearly a pound. There were no leaks, drips or puddles around the can - it simply evaporated, right through the jug! This simple test convinced us that the thicker CARB jug did its job in preventing vaporous emissions.

Shopping Tips

When selecting for your next jerry jug, here are some helpful things to keep in mind:

Think about your boat's design and where the fuel fill is. The railing on our boat made using some jugs much more difficult than others. If there are any obstacles around your deck-fill, look for a jug with a design that will maneuver around them easily.

The jerry jugs we tested all feature maximum fill level lines and graduated volume marks. Some also provided extra capacity for additives. These helpful additions make things easier for those who premix their fuel.

Some jerry jugs also have child-safety features and locks, many of which were cumbersome to use and when not used properly could result in more spills. Make sure you understand these features before making your purchase.

Most of our CARB jugs took more than three minutes to empty and the flow was uneven, which caused some splashing. Look for an extra handhold on the side to help in balancing the jug and insure a steadier flow.

Since speed should not be the goal, we suggest looking for a gas container that is comfortable to carry, hold and balance. The problem of spilling fuel may not be completely eliminated, but, when compared to the traditional jerry jug design the new jugs are a vast improvement.

Ultimately, if you go slow, pour deliberately, and use and absorbent pad, most spills can be avoided, or at least captured before it can reach our precious waters.

Safety tip: Never fill a fuel container in the trunk of your car or on a truck bed - always place it on the ground to create an electrical conductor which prevents sparks from static!

- By Ted Sensenbrenner and Amanda Suttles